Formwork Placing tools - Walls: Tool configuration

Setting up the tool for a new formwork supplier

The configuration is done with help of comma separated files (.csv), which can be edited with Excel or any text editor. Each formwork tool component has its own configuration. The configuration files can be located in any of the system folders or in the sub folder named 'Formwork tools' under the model folder.

After installing the latest version of the tools demo versions of the config files can be found in this folder: \Environments\common\system\CIP\

The configuration files are typically named by the formwork supplier and/or the product families. There can be any number of files, and the files are identified with a certain suffix:

- xxxx.FormworkTools.Panels.csv – Setup the formwork panels

- xxxx.FormworkTools.Ties.csv – Setup the ties for the tie placing tool

- xxxx.FormworkTools.TieSpacers.csv – Setup the tie spacers placed by the tie placing tool

- xxxx.FormworkTools.Clamps.csv – Setup the clamps

- xxxx.FormworkTools.Braces.csv – Setup the braces

- xxxx.FormworkTools.Platforms.csv – Setup the pouring platforms

- xxxx.FormworkTools.Walers.csv – Setup the walers

- xxxx.FormworkTools.Conditions.csv – Setup the conditions (corners, pilasters and or bulkheads)

- xxxx.FormworkTools.Fillers.csv – Setup the fillers

Each of the files with a specific suffix controls one of the tools. The files contain varying number of columns. The columns are named within the header line, which is the first line that is not a comment line.

Configuring the panel placing tool (*.FormworkTools.Panels.csv)

For each panel add/modify one row to the file, and on this row, specify columns as follows:

| Column title | Description |

|---|---|

| Supplier | Supplier name, this is typically the same for all rows. |

| Family | Family name, which is shown in the ‘Family’ list. |

| Name | This is a unique panel name. |

| PanelName | This is the name of the custom part that will be inserted in the model. |

| PanelAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

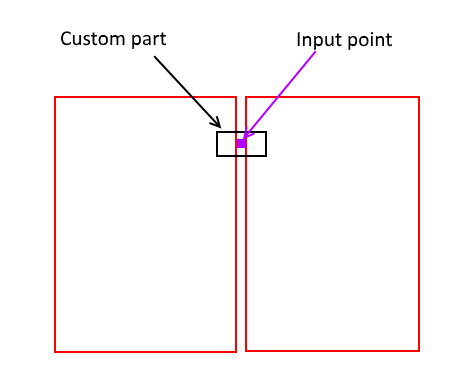

| PanelInputOrder | This option controls how the final locations of the input points are set in relation to the default generic start and end points. The possible values are:

Image

|

| PanelPlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in plane view. The options are MIDDLE, LEFT, RIGHT. |

| PanelPlaneOffset | This is the offset in plane. The default value is 0. |

| PanelRotation | This is the ‘Rotation’ to be used to insert the custom part in plane view. The options are FRONT, TOP, BACK and BELOW. |

| PanelRotationOffset | This is the rotation offset in degrees.The default value is 0. |

| PanelDepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in plane view. The options are MIDDLE, FRONT, BEHIND. |

| PanelDepthOffset | This is the offset in depth. The default value is 0. |

| PanelStartOffset | This is the offset of the actual start point from the generic start point in local coordinate system. The offset is given as x, y & z values separated by a space or colon and enclosed in parenthesis (0 100 0). If no value is given, a zero offset (0 0 0) is assumed. |

| PanelEndOffset | This is the offset of the actual end point from the generic end point in local coordinate system. The offset is given as x, y & z values separated by a space or colon and enclosed in parenthesis (0 100 0). If no value is given, a zero offset (0 0 0) is assumed. |

| HeightProperty | The name of the height property in the custom part. If the height is fixed, this is empty. |

| HeightValue | The height of the panel. Note that the tool does not get the height from the component catalog but from this file. |

| WidthProperty | The name of the width property in the custom part. If the width is fixed, this is empty. |

| WidthValue | The width of the panel. Note that the tool does not get the width from the component catalog but from this file. |

| ThicknessProperty | The name of the width property in the custom part. If the width is fixed, this is empty. |

| ThicknessValue | The thickness of the panel. Note that the tool does not get the thickness from the component catalog but from this file. |

| TieX | These are the X locations of the ties within the preset pattern. Values must be enclosed in () and separated by spaces. |

| TieY | These are the Y locations of the ties within the preset pattern. Values must be enclosed in () and separated by spaces. |

|

TiePickX |

With these settings you can define the possible X and Y locations of the ties when placing and picking a single tie. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (TiePickX and TiePickY) or X and Y value pairs in one field (TiePickXY). Values must be enclosed in () and separated by spaces. |

| ClampX | These are the X locations used to place clamps at horizontal top/bottom edges. Values must be enclosed in () and separated by spaces. |

| ClampY | These are the Y locations used to place clamps at vertical left/right edges. Values must be enclosed in () and separated by spaces. |

| ClampPickX ClampPickY or ClampPickXY |

With these settings you can define the possible X and Y locations of clamps when placing and picking a single clamp. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (ClampPickX and ClampPickY) or X and Y value pairs in one field (ClampPickXY). Values must be enclosed in () and separated by spaces. |

| BraceX BraceY or BraceXY |

With these settings you can define the preset pattern for the braces. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (BraceX and BraceY) or X and Y value pairs in one field (BraceXY). Values must be enclosed in () and separated by spaces. |

| BraceTiltedX BraceTiltedY or

BraceTiltedXY |

With these settings you can define the preset pattern for the braces when the panel is tilted. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (BraceTiltedX and BraceTiltedY) or X and Y value pairs in one field (BraceTiltedXY). Values must be enclosed in () and separated by spaces. |

| BracePickX BracePickY or BracePickXY |

With these settings you can define the possible X and Y locations of the braces when placing and picking a single brace in a panel. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (BracePickX and BracePickY) or X and Y value pairs in one field (BracePickXY). Values must be enclosed in () and separated by spaces. |

| BraceTiltedPickX BraceTiltedPickY or BraceTiltedPickXY |

With these settings you can define the possible X and Y locations of the braces when placing and picking a single brace in a tilted panel. You have two alternatives for configuration: You can either specify the X and Y values separately in two fields to define a regular grid of locations, or if your panels require an irregular pattern, you can specify a list of X and Y value pairs. Always define the X and Y values in two separate fields (BraceTiltedPickX and BraceTiltedPickY) or X and Y value pairs in one field (BraceTiltedPickXY). Values must be enclosed in () and separated by spaces. |

| WalerEdgeOffset | This is the offset of the waler input point (=location of the clamp 1 and/or clamp 2) from the panel edge when the walers are placed automatically. Image

|

| WalerX | This is the X-locations used to place walers automatically at horizontal top/bottom edges. The vertical (Y) location is defined by 'WalerEdgeOffset' from the top/bottom edge. Values shall be enclosed in () and separated by commas or spaces |

| WalerY | This is the Y-locations used to place walers automatically at vertical left/right edges. The horizontal (X) location is defined by 'WalerEdgeOffset' from left/right edge. Values shall be enclosed in () and separated by commas or spaces |

| WalerPickX | With these settings you can define the possible X locations of the walers when placing and picking a single waler. Values must be enclosed in () and separated by commas or spaces. |

| WalerPickY | With these settings you can define the possible Y locations of the walers when placing and picking a single waler. Values must be enclosed in () and separated by commas or spaces. |

Panel local coordinate system

The configuration of all accessories that can be added to panels is done in the local coordinate system of the panel. The origin of the panel is located at the center point of the panel.

Configuring the tie placing tool (*.FormworkTools.Ties.csv)

A generic tie consists of three custom components: A bolt that usually goes through the wall, and two locks on both sides of the formwork.

For each tie, add/modify one row, and on this row, specify the columns as follows:

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is the tie name, which can be unique, or multiple tie configurations may have the same name. When multiple tie configurations have the same name, the tool automatically selects the first tie based on the wall thickness. |

| MaxLength | This is the maximum possible length of the tie. It is measured from outer faces of the two formwork panels on opposite sides. |

| LengthProperty | If the tie custom part is parametric and has a parameter controlling the effective length, this is the name of the 'length' property. |

| Part1Name | This is the name of the custom part 1 (='bolt'). |

| Part1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part1PlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1PlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1Rotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1RotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part1EndOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| Part2Name | This is the name of the custom part 2 which typically is the 'lock' on the front side of the main formwork panel. |

| Part2Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part2StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part2EndOffset | This is the location of the second insertion point in relation to the 'input point 1'. |

| Part2.... | For custom part 2, you can specify the same fields as for custom part 1. |

| Part3Name | This is the name of the custom part 3, which typically is the 'lock' on the back side of the main formwork panel. |

| Part3Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part3StartOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| Part3EndOffset | This is the location of the second insertion point in relation to the 'input point 2'. |

| Part3 ... | For custom part 3, you can specify the same fields as for custom part 1. |

Configuring the spacers for the tie placing tool (*.FormworkTools.TieSpacers.csv)

A generic tie spacer consists of three custom components: A 'tube' that usually goes through the wall, and two optional 'cones' at each side of the wall.

For each tie spacer, add/modify one row, and on this row, specify the columns as follows:

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is the tie spacer name, it can be unique, or multiple tie spacer configurations may have the same name. When multiple tie spacer configurations have the same name, the tool automatically selects the first suitable tie spacer based on the wall thickness. |

| MinLength | This is the minimum possible length of the tube. It is measured from inner faces of the two formwork panels on opposite sides. |

| MaxLength | This is the maximum possible length of the tube. It is measured from inner faces of the two formwork panels on opposite sides. |

| LengthProperty | If the tie spacer custom part is parametric and has a parameter controlling the effective length, this is the name of the 'length' property. |

| SpacerTubeName | This is the name of the custom part (='tube') |

| SpacerTubeAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| SpacerTubePlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubePlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubeRotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubeRotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubeDepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubeDepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| SpacerTubeStartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| SpacerTubeEndOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| StartConeName | This is the name of the custom part which typically is the 'cone' on the front side of the main formwork panel. |

| StartConeAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| StartConeStartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| StartConeEndOffset | This is the location of the second insertion point in relation to the 'input point 1'. |

| StartCone.... | For custom part 2, you can specify the same fields as for custom part 1. |

| EndConeName | This is the name of the custom part which typically is the 'cone' on the back side of the main formwork panel. |

| EndConeAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| EndConeStartOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| EndConeEndOffset | This is the location of the second insertion point in relation to the 'input point 2'. |

| EndCone ... | For custom part 3, you can specify the same fields as for custom part 1. |

Configuring the clamp placing tool (*.FormworkTools.Clamps.csv)

The generic clamp contains one custom part. The input points are at edges of the two panels and thus the clamp can be parametric in terms of the filler space

if needed.

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is the clamp name, it shall be unique |

| CenterInput | When ‘YES’, the first insertion point is in the middle of the seam of the two panels. If the value is ‘NO’, the insertion points are offset from the edge of the panels. |

| FillerGapProperty | If the clamp custom part is parametric, and the parameter can adjust the gap between two panels, this is the name of that parameter. This field is empty if the clamp is not parametric. |

| MaxFillerGap | This value is used when clamps or walers are added automatically along with a formwork filler. When ever the free space (=width of the filler) is less or equal to the given 'MaxFillerGap' the tool will insert clamps. If the free space is greater than the given 'MaxFillerGap' then the tool will insert walers. |

| Part1Name | This is the name of the clamp custom part 1. |

| Part1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part1PlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1PlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1Rotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1RotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part1EndOffset | This is the location of the second insertion point in relation to the 'input point 1'. |

Note that to create the brackets with some additional bolts/locks, you need to make a new custom part containing both the bracket and all necessary fittings:

Configuring the brace placing tool (*.FormworkTools.Braces.csv)

A generic brace may consists of five custom parts, which are inserted in the model by using three input points. You can select the the upper/lower brace separately. In the brace configuration file, the upper and lower braces are defined separately (own row for both).

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is the brace name shown in a list. Note that if you have several rows with the same name, the tool will select the best brace based on min/max length. |

| Type | This is the type of the brace. The options are 'Upper' or 'Lower'. |

| MinLength | This is the minimum possible length of the main brace measured from input point 1 to input point 2. |

| MaxLength | This is the maximum possible length of the main brace measured from input point 1 to input point 2. |

| LengthProperty | If the brace custom part is parametric and has a parameter controlling the effective length, this is the name of the 'length' property. At insertion it will get the actual length value between points 1 and 2. |

| BraceName | This is the name of the custom part for the upper or lower brace which will be inserted into the model. |

| BraceAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| BracePlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in plane view. |

| BracePlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in plane view. |

| BraceRotation | This is the ‘Rotation’ to be used to insert the custom part in plane view. |

| BraceRotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in plane view. |

| BraceDepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in plane view. |

| BraceDepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in plane view. |

| BraceStartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| BraceEndOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| Bracket1Name | This is the name of the custom part for the top bracked (upper brace) or bottom bracket (lower brace) which will be inserted into the model. |

| Bracket1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Bracket1StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Bracket1EndOffset | This is the location of the second insertion point in relation to the 'input point 3' |

| Bracket1.... | For custom part 2, you can specify the same fields as for custom part 1. |

| Bracket2Name | This is the name of the custom part for the floor bracket, which will be inserted into the model. If both upper and lower brace have a definition for the bracket, the bracket defined for the lower brace will be created. |

| Bracket2Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Bracket2StartOffset | This is the offset of the first insertion point in relation to 'input point 2' |

| Bracket2EndOffset | This is the location of the second insertion point in relation to the 'input point 2' |

| Bracket2 ... | For custom part 3, you can specify the same fields as for custom part 1. |

Configuring the pouring platform placing tool (*.FormworkTools.Platforms.csv)

A generic pouring platform contains two custom parts, which are inserted in the model as a linear array of custom parts.

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is a unique pouring platform name. |

| Type | The type of the platform (A or B). The length of the array is defined with start & end points of the platform. The custom part placing has two methods:

|

| Length | This is the effective length of one platform element. |

| Width | This is the width of the platform. |

| Spacing | This is the spacing between the custom parts in the array. |

| Part1Name | This is the name of the custom part 1. |

| Part1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part1PlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1PlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1Rotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1RotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part1EndOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part2Name | This is the name of the custom part 2. |

| Part2Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part2StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part2EndOffset | This is the location of the second insertion point in relation to the 'input point 1'. |

| Part2.... | For custom part 2, you can specify the same fields as for custom part 1. |

Configuring the waler placing tool (*.FormworkTools.Walers.csv)

A generic waler consists of three custom parts, the waler beam and two clamp devices as shown in following picture. The generic input points are located in the outer face of the panel.

| Column title | Description |

|---|---|

| Supplier | Supplier name |

| Family | Family name |

| Name | This is the waler name. The name can be unique, or multiple waler configurations may have the same name. When multiple waler configurations have the same name, the tool automatically selects the shortest waler based on the actual length measured between the input points. Note that typically you can specify the same waler with a unique name and a common name. This way you can select the common name and let the system select the waler based on input length. By selecting the unique name you can force the usage of a certain waler configuration. |

| MaxLength | This is the maximum possible effetive length of the waler. It is measured from first to second input points (=clamp locations) so it is typically little less than the physical length. |

| MinLength | This is the minimum length of a waler with variable length. For fixed length walers leave the field empty or give same value as for max length. |

| BeamName | This is the name of the clamp custom part 1. |

| BeamAttributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| BeamPlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamPlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamRotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamRotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamDepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamDepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| BeamStartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| BeamEndOffset | This is the location of the second insertion point in relation to the 'input point 1'. |

| Clamp1Name | This is the name of the clamp 1 custom part. |

| Clamp1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Clamp1StartOffset | Offset of the first insertion point in relation to 'input point 1' |

| Clamp1EndOffset | This is the location of the second insertion point in relation to the 'input point 1' |

| Clamp1.... | For custom clamp 1, you can specify the same fields as for waler beam custom part |

| Clamp2Name | This is the name of the clamp 2 custom part. |

| Clamp2Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Clamp2StartOffset | Offset of the first insertion point in relation to 'input point 1' |

| Clamp2EndOffset | This is the location of the second insertion point in relation to the 'input point 1' |

| Clamp2.... | For custom clamp 2, you can specify the same fields as for waler beam and clamp 1 custom parts |

Configuring the conditions for condition placing tool (*.FormworkTools.Conditions.csv)

A condition in the context of the formwork tools is wide and covers L, T and X corners, pilasters, pour stops and columns. The final condition formwork is divided into two or more subassemblies depending on the condition type as shown in the table below.

Recommended way to define is to use Conditon setup or define configurations manually as follows:

- Model the full condition assembly interactively with the basic products (custom parts), beams and/or filler tools.

- Create the necessary subassemblies using the two wizards. At this step you split the content of the complete condition into named subassemblies. When these subassemblies are inserted in the model, the final location is parametric in the sense that the location depends on the actual geometry of the concrete structure.

- Insert a new condition specification into the condition configuration file.

The various 'condition' types supported by the formwork condition placing tool are described in the following table.

| 'Condition' type | Description |

|---|---|

| L corner (L) | For L corner you can specify the inner corner subassembly (1) and the exterior corner subassembly (2). Image

The corner subassembly is defined with the ‘Corner subassembly wizard’. With the wizard you can specify two sets of formwork items, which will be rotated according to the joining walls when the corner is placed in the model. The two corner subassemblies 1 and 2 are inserted according to the thickness of the joining walls. |

| T corner (T) | For T corner you can specify two inner corners (1+2) and the back panel (3). Image

The corner subassembly is defined with the ‘Corner subassembly wizard’. The back panel subassembly is defined with the ‘Subassembly wizard‘, and it contains a single insertion point + direction. When the tee corner is placed in the model, the insertion point of the panel subassembly is located at the intersection of the joining wall center line and the exterior face of the (horizontal) wall. |

| X corner (X) | For X corner you can specify the four inner corners (1-4). Image

|

| Corner pilaster (CP) | For corner pilaster you can specify one inner corner subassembly (1) and three extern corner subassemblies (2-4). Image

|

| Pilaster (P) | For pilaster you can specify two inner corners (1&4), two external corners (2&3) and the back panel (5). Image

|

| Pilaster inside corner (IP) | For inner pilaster you can specify one external corner (1) and three inner corners (2-3). Image

|

| Bulkhead (B) | For bulkhead you can specify two external corners (1&2) and two middle panels (3&4). Panel 4 will be located at end of pour and all other sub items will be offset by the given dimension. Image

|

| Column (COL) | For column you can specify four panel assemblies and/or four corner assemblies. Image

|

Creating a corner sub assembly

The corner subassembly is the building block for one side of the L corner or any of the inner corners in the T and X corners. To create a named corner sub assembly:

- First model all formwork objects needed. Only beams and/or custom parts can be used for modeling, so if you have other components, you need to explode them.

- Decide which object should rotate with the 1st direction, and which objects should rotate with the 2nd edge at the corner if/when the corner angle varies.

- Start the tool ‘Formwork corner sub assembly setup wizard’ and

- Pick the corner point (see image).

- Pick the point to identify the 1st direction.

- Select the corner items (custom parts and/or beams) at the 1st side of the corner.

- Pick the point to identify the 2nd direction.

- Select the corner items (custom parts and/or beams) at the 2nd side of the corner.

- Give the name and click ‘Finish’ to save the detailed half of the corner into an external file.

Note that the wizard should be run separately for the inner corner (red dots) and external corner (blue dots), and you need to ensure not to include same objects twice as that would lead to duplicate objects in the model.

Creating a panel sub assembly

The panel subassembly is the building block of the formwork at back side of the T corner and at pilasters. To create a named panel sub assembly:

- First model all needed formwork objects (custom parts and/or beams) needed.

- Start the tool ‘Formwork panel sub assembly setup wizard’ and

- Pick the center point of the object at the back of the wall (see image). This will be used as the insertion point when this panel subassembly is inserted in an actual T corner.

- Picks the point to identify the direction.

- Select the formwork items (custom parts and/or beams) forming the panel subassembly.

- Give a name and click ‘Finish’ to save the detailed panel and accessories into an external file.

Controlling the behavior of conditions with mirroring

Note that when you define the corner subassemblies, it may happen that the left-hand corner needs to be placed in a right-hand location. When this happens, the corner subassembly needs to be mirrored. Mirroring custom parts or items is not always possible, especially when the item is not symmetric in any direction. The condition placing tool can use four different methods for mirroring. With the configuration file xxxxx.SubAssemblyItems.ini you can control which method will be used for a certain corner subassembly item. The file contains the mirroring method keyword, and after the keyword you can introduce the names of the items or partial name tags to identify multiple matching items.

| Mirroring method | Description |

|---|---|

| Move Image

|

This is the default method. The custom part or item is moved by an offset measured from the mirroring line to the center of the custom part or item. |

| RotateAroundZ Image

|

The input points are rotated 180 degrees around the center point at the mirroring line. |

| RotateAroundAxis

Image

|

The input points are first rotated 180 degrees around the mirroring line and then the custom part is rotated 180 degrees around the input axis. |

| Mirror Image

|

The input point locations are mirrored and then the start and end points are swapped. |

| FlipLocalXY | The item/custom part is moved and local X and Y axis's at center are flipped (=rotated around local Z 180 degrees) |

| FlipLocalXZ | The item/custom part is moved and local X and Z axis's at center are flipped (=rotated around local Y 180 degrees) |

| FlipLocalYX | The item/custom part is moved and local Y and Z axis's at center are flipped (=rotated around local X 180 degrees) |

| TurnUpSideDown | The item/custom part is moved and "mirroring" is done by turning the component up-side-down (in global vertical direction) |

Example of content in a configuration (xxxxx.SubAssemblyItems.ini) file.

// This file allows you to define how items and custom parts in corner sub assemblies // are handled when placing the right handed corner into left handed situation or vice versa. // // By default items are just moved and no true mirroring happens. In following lines you can specify // the mirroring methods used for certain items or custom parts. You can introduce full names or partial names. // // The possible methods are: // #Mirror - input points are mirrored // #RotateAroundAxis - input points are mirrored and the item/custom part is rotated 180 degrees around the axis: // #RotateAroundZ - input points are rotated 180 degrees around the center point // #FlipLocalXY - the item/custom part is moved and local X and Y axis's at center are flipped (=rotated around local Z 180 degrees) // #FlipLocalXZ - the item/custom part is moved and local X and Z axis's at center are flipped (=rotated around local Y 180 degrees) // #FlipLocalYZ - the item/custom part is moved and local Y and Z axis's at center are flipped (=rotated around local X 180 degrees) // #TurnUpSideDown - the item/custom part is moved and "mirroring" is done by turning the component up-side.down // // Just list the names or partial names following the method keyword. Do not change the key words. // #Mirror _FIXING_BOLT #RotateAroundAxis DOKA-3D-583002000 #RotateAroundZ _INSIDE _OUTSIDE _CORNER _LEFT _RIGHT #FlipLocalXY #FlipLocalXZ #FlipLocalYX #TurnUpSideDown |

Configuring the fillers for filler placing tool (*.FormworkTools.Fillers.csv)

With the filler placing tool you can create the filler by inserting timber beams or plywood and timber studs and/or specific custom parts in the model. The creation of these model objects depends on the actual space to be filled. The basic principle of the creation of the various items is the following:

- If the space to be filled is larger than the given minimum plywood width, the filler tool will create the plywood (=contour plate) and the timber studs.

- If the space to be filled is smaller than the minimum plywood width, or plywood is not specified, the actual space is filled by one or more timber beams or custom parts. The target is to fill the actual space as completely as possible. The largest beams and/or custom parts are preferred and smaller pieces are created only when the space is smaller than the size of the larger pieces.

| Filler built with plywood and studs Image

|

Filler built with timber beams Image

|

Filler built with custom part Image

|

To configure the filler tool, you can specify the properties for timber beam, plywood and settings for one to ten alternatives of custom parts.

| Column title | Description |

|---|---|

| Supplier | The supplier name |

| Family | The family name |

| Name | This is a unique filler name. |

| TimberWidths | This is a list of available timber beam widths (10 20 50 100). |

| TimberDepth | This is the depth of the timber beam. |

| TimberAssPrefix | This is the assembly number prefix. |

| TimberAssStartNo | This is the assembly number start number. |

| TimberPartPrefix | This is the part number prefix. |

| TimberPartStartNo | This is the part number start number. |

| TimberName | This is the name of the timber beam. |

| TimberClass | This is the class. |

| TimberFinish | This is the finish. |

| TimberMaterial | This is the material. |

| StudWidth | This is the width of the timber stud. |

| StudDepth | Tis is the depth of the timber stud. |

| StudAssPrefix | This is the assembly number prefix. |

| StudAssStartNo | This is the assembly number start number. |

| StudPartPrefix | This is the part number prefix. |

| StudPartStartNo | This is the part number start number. |

| StudName | This is the name of the timber stud. |

| StudClass | This is the class. |

| StudFinish | This is the finish. |

| StudMaterial | This is the material. |

| PlywoodWidth | This is the minimum width of the plywood. The actual width depends on the actual space to be filled. |

| PlywoodThickness | This is the thickness of the plywood. |

| PlywoodAssPrefix | This is the assembly number prefix. |

| PlywoodAssStartNo | This is the assembly number start number. |

| PlywoodPartPrefix | This is the part number prefix. |

| PlywoodPartStartNo | This is the part number start number. |

| PlywoodName | This is the name of the plywood part. |

| PlywoodClass | This is the class of the plywood part. |

| PlywoodFinish | This is the finish of the plywood part. |

| PlywoodMaterial | This is the material of the plywood part. |

| Part1Name | This is the name of the custom part 1. |

| Part1Attributes | This is the attribute file (saved from component dialog) to be used when the custom part will be inserted into model. |

| Part1PlanePosition | This is the ‘Position in plane’ to be used to insert the custom part in the face view of the main formwork panel. |

| Part1PlaneOffset | This is the ‘Offset in plane’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1Rotation | This is the ‘Rotation’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1RotationOffset | This is the ‘Rotation offset’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthPosition | This is the ‘Position in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1DepthOffset | This is the ‘Offset in depth’ to be used to insert the custom part in face view of the main formwork panel. |

| Part1StartOffset | This is the offset of the first insertion point in relation to 'input point 1'. |

| Part1EndOffset | This is the offset of the first insertion point in relation to 'input point 2'. |

| Part1Length | This is the lenght of the custom part which is also the space to fill if/when this custom part is added to the model. |

| Part1Height | This is the height of the custom part. |

| Part2 .... Part3 .... . . . Part10 ... |

In addition to custom part 1, you can specify up to nine other custom parts. In practice, at least the 'PartXLength' needs to be different for all specified custom parts. The tool selects the part with most suitable length depending on the actual space to be filled. |